Journal of Tropical Oceanography ›› 2026, Vol. 45 ›› Issue (1): 188-197.doi: 10.11978/2025141CSTR: 32234.14.2025141

Research and optimization on calibration of marine cable insulation oil sensors*

ZHUANG Ruixue1( ), XU Zhantang2, SHI Zhen2(

), XU Zhantang2, SHI Zhen2( ), ZHANG Jun1, XIE Mengyuan1, XIONG Lanlan3, HU Xin3, ZHAO Kequan4

), ZHANG Jun1, XIE Mengyuan1, XIONG Lanlan3, HU Xin3, ZHAO Kequan4

- 1Guangdong Provincial Engineering Technology Research Center on Visible Light Communication, Jinan University, Guangzhou 510632, China

2Laboratory of Tropical Oceanography, South China Sea Institute of Oceanology, Chinese Academy of Sciences, Guangzhou 510301, China

3Guangdong Center for Marine Development Research, Guangzhou 510220, China

4University of Chinese Academy of Sciences, Beijing 100049, China

-

Received:2025-08-20Revised:2025-09-03Online:2026-01-10Published:2026-01-30 -

Contact:SHI Zhen. email:shizhen@scsio.ac.cn -

Supported by:2024 Annual Ministry-Provincial Cooperation Project of the Ministry of Natural Resources(2024ZRBSHZ103); Research on Trace Detection Methods for Insulating Liquids in Oil-filled Submarine Cables(QT2023-09-79); Basic and Applied Basic Research Foundation of Guangdong Province(2025A1515012033)

CLC Number:

- P714.4

Cite this article

ZHUANG Ruixue, XU Zhantang, SHI Zhen, ZHANG Jun, XIE Mengyuan, XIONG Lanlan, HU Xin, ZHAO Kequan. Research and optimization on calibration of marine cable insulation oil sensors*[J].Journal of Tropical Oceanography, 2026, 45(1): 188-197.

share this article

Add to citation manager EndNote|Reference Manager|ProCite|BibTeX|RefWorks

Tab. 1

Comparison of response signal values under different illumination conditions"

| 组别 | 空白信号值 | 0.52mg·L−1信号值 | 0.79mg·L−1信号值 |

|---|---|---|---|

| 实验组(阳光照射)测量值 | 0.0182008 | 0.0578266 | 0.0768013 |

| 0.0182312 | 0.057790875 | 0.0766355 | |

| 0.0181955 | 0.0579012 | 0.0764461 | |

| 平均值 | 0.01821±(4.8×10−4) | 0.05782±(8.7×10−4) | 0.07663±(6.8×10−4) |

| 对照组(遮光条件)测量值 | 0.018188 | 0.0578846 | 0.0767259 |

| 0.0182776 | 0.0578263 | 0.0769018 | |

| 0.0182434 | 0.0579099 | 0.0762525 | |

| 平均值 | 0.001824±(5.1×10−4) | 0.05787±(6.3×10−4) | 0.07663±(7.4×10−4) |

| P | 0.83199 | 0.80012 | 0.99593 |

Tab. 3

Comparison of sample testing results by two methods"

| 样品 编号 | 测定 次数 | 本方法测量浓度/(mg·L−1 ) | 荧光光度法测量浓度/(mg·L−1 ) | 相对偏差 |

|---|---|---|---|---|

| 1 | 1 | 0.384 | 0.366 | 6.11% |

| 2 | 0.383 | 0.377 | ||

| 3 | 0.380 | 0.338 | ||

| 平均值 | 0.382 | 0.360 | ||

| 2 | 1 | 0.788 | 0.772 | 5.72% |

| 2 | 0.791 | 0.753 | ||

| 3 | 0.791 | 0.718 | ||

| 平均值 | 0.790 | 0.748 | ||

| 3 | 1 | 1.982 | 1.791 | 9.49% |

| 2 | 1.987 | 1.792 | ||

| 3 | 1.991 | 1.860 | ||

| 平均值 | 1.987 | 1.814 | ||

| 4 | 1 | 3.594 | 3.379 | 5.88% |

| 2 | 3.604 | 3.410 | ||

| 3 | 3.605 | 3.415 | ||

| 平均值 | 3.601 | 3.401 |

| [1] |

郭晶晶, 王岚云, 2015. 紫外法和荧光法测定海水油类质控指标研究[J]. 化学工程与装备, (11): 199-204, 228 (in Chinese).

|

| [2] |

黄宏新, 2011. 高压充油电缆检测基础问题的研究[D]. 北京: 华北电力大学.

|

|

|

|

| [3] |

李建超, 邓琥, 武志翔, 等, 2012. 水中油在线荧光检测系统的标定研究[J]. 自动化与仪表, 27(4): 53-56.

|

|

|

|

| [4] |

李义, 禹海清, 董建芳, 等, 2010. 加标回收在水质分析中的应用及回收率计算方法[J]. 岩矿测试, 29: 597-600.

|

|

|

|

| [5] |

梁树生, 朱志雄, 2024. 荧光法和紫外法测定海水中石油类的对比研究[J]. 广东化工, 51(20): 16-19.

|

|

|

|

| [6] |

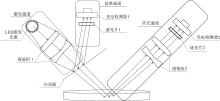

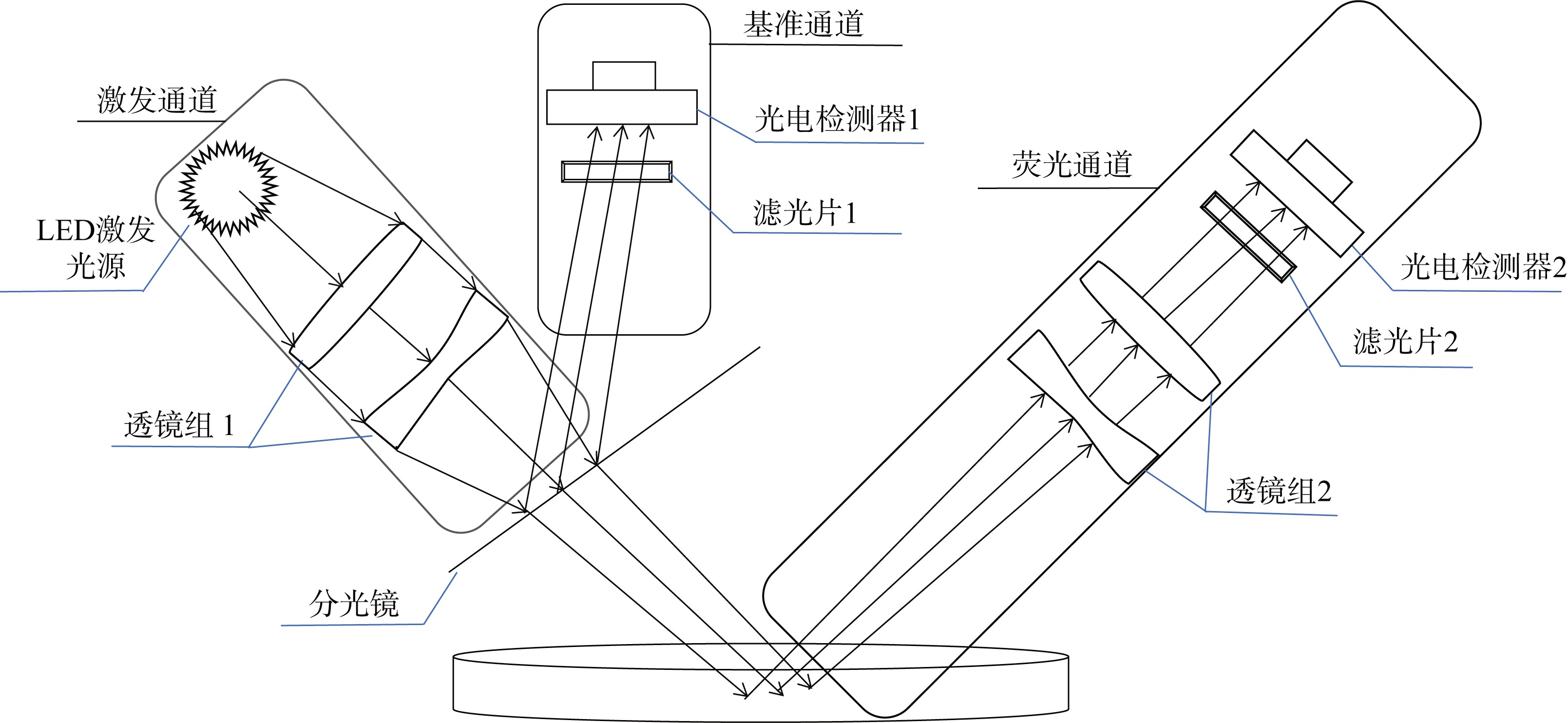

柳杰, 傅明利, 冯宾, 等, 2025. 基于荧光法的海底电缆绝缘油示踪检测装置[J]. 高电压技术: 1-11.

|

|

|

|

| [7] |

栾晓宁, 王春艳, 李颖, 等, 2009. 从浓度定量分析探讨异丙醇作原油萃取剂的可行性[J]. 海洋湖沼通报, 31(2): 151-156.

|

|

|

|

| [8] |

罗登林, 丘泰球, 卢群, 2005. 超声波技术及应用(Ⅱ): 声化学技术在日化工业中的应用[J]. 日用化学工业, 35(6): 393-395.

|

|

|

|

| [9] |

马国明, 秦炜淇, 王思涵, 等, 2025. 海底电缆状态分布式光纤监测技术研究综述[J]. 中国电机工程学报, 45(1): 370-388.

|

|

|

|

| [10] |

彭三兵, 张鹏, 何斌, 等, 2024. 基于紫外荧光法的海上平台钻井液含油率检测研究[J]. 山东化工, 53(23): 189-191, 197.

|

|

|

|

| [11] |

王赛男, 许赞, 刘亮, 等, 2023. 一种便携式荧光测油仪在海上溢油应急监测中的适用性研究[J]. 中国环境监测, 39(3): 190-196.

|

|

|

|

| [12] |

新疆维吾尔自治区市场监督管理局, 2021. 水质石油类的测定荧光光度法(DB 65/T 4369—2021)[S].

|

|

Xinjiang Uygur Autonomous Region Market Supervision and Administration Bureau, 2021. Water quality-determination of petroleum-hydrocarbons-fluorescence spectrophotometric method (DB 65/T4369-2021)[S]. (in Chinese).

|

|

| [13] |

薛晓杰, 王诚熹, 姜巍巍, 2018. 正己烷紫外分光光度法测定地表水中石油类的方法改进[J]. 净水技术, 37(S1), 34-35, 60.

|

|

|

|

| [14] |

杨铨, 冯伟, 邢龙辉, 等, 2024. 油液监测黏度传感器标定方法优化研究[J]. 润滑与密封, 49(5): 171-176.

|

|

|

|

| [15] |

杨书会, 王延圣, 王文亮, 等, 2024. 多糖乳液的制备、乳化特性的影响因素及其应用研究进展[J]. 食品工业科技, 45(14): 398-407.

|

|

|

|

| [16] |

叶欣, 张雪容, 王珏, 2010. 自动萃取仪对水中油类的萃取效率研究[J]. 福建分析测试, 19(3): 46-48.

|

|

|

|

| [17] |

张飞, 2015. 水中石油类和动植物油类萃取方式的比对研究[J]. 环境与发展, 27(2): 95-97.

|

|

doi: 10.1016/j.envdev.2018.07.004 |

|

| [18] |

赵广立, 冯巍巍, 付龙文, 等, 2014. 基于紫外荧光法检测水中油含量的浸入式传感装置的研究[J]. 海洋通报, 33(1): 77-83.

|

|

|

|

| [19] |

中华人民共和国国家质量监督检验检疫总局, 2006. 荧光分光光度计( JJG 537-2006)[S].

|

|

General administration of quality supervision, inspection and quarantine of the People's Republic of China, 2006. Fluorescence Spectrophotometer (JJG 537-2006)[S]. (in Chinese).

|

|

| [20] |

中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会, 2007. 海洋监测规范第4部分:海水分析(GB 17378. 4-2007)[S]. 北京: 中国标准出版社.

|

|

General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China, 2007. Specifications for marine monitoring-Part 4: seawater analysis (GB 17378. 4-2007)[S]. Beijing: Standards Press of China (in Chinese).

|

|

| [21] |

doi: 10.1016/j.marpolbul.2023.115887 |

| [22] |

doi: 10.1016/j.ijleo.2018.12.073 |

| [23] |

|

| [24] |

doi: 10.1016/j.rser.2024.114473 |

| [25] |

doi: 10.1109/TGRS.2013.2242476 |

| [26] |

|

| [27] |

doi: 10.1016/j.rse.2019.111421 |

| [28] |

doi: 10.1016/j.rse.2012.03.024 |

| [29] |

doi: 10.1016/j.rse.2020.111778 |

| [30] |

pmid: 19474993 |

| [31] |

doi: 10.1016/j.engfailanal.2024.109038 |

| [32] |

doi: 10.1196/nyas.2008.1130.issue-1 |

| [33] |

|

| [34] |

|

| [35] |

doi: 10.1016/j.ultsonch.2023.106323 |

| [36] |

doi: 10.1016/j.ultsonch.2021.105501 |

| [37] |

doi: 10.1364/AO.426451 |

| [38] |

doi: 10.1007/s10765-013-1446-7 |

| [1] | YANG Shaoqiong, CHENG Dan, CHEN Guangyao, LUO Chenyi, NIU Wendong, MA Wei, FA Shuai. Review on the application of underwater gliders for observing typical ocean phenomena [J]. Journal of Tropical Oceanography, 2022, 41(3): 54-74. |

| [2] | Wenxi CAO, Zhaohua SUN, Cai LI, Guowang ZOU. Biofouling protection for water quality monitoring buoy and sensors [J]. Journal of Tropical Oceanography, 2018, 37(5): 7-12. |

| [3] | Huawei QIN, Zhuo TAO, Huaiming LI, Xihe YUE, Zhen CAI, Sheng CHEN, Hongwei ZHOU, Ying YE. Development and application of chemical sensor for hydrothermal vents detection [J]. Journal of Tropical Oceanography, 2018, 37(3): 86-92. |

| [4] | Jiguang LI, Dongkai WANG. Research on ghost suppression and notch compensation of dual-sensor ocean bottom cable data [J]. Journal of Tropical Oceanography, 2018, 37(2): 100-104. |

| [5] | DONG Xian-xin, JIANG Kai, CHEN Hang, YE Shu-ming. A design of deep-sea extreme environment simulator [J]. Journal of Tropical Oceanography, 2014, 33(2): 101-108. |

| [6] | CAO Wen-xi,YANG Yue-zhong,ZHANG Jing-xiang,KE Tian-cun,LU Gui-xin,LI C. Design and test of moored optical buoy [J]. Journal of Tropical Oceanography, 2010, 29(2): 1-6. |

| [7] |

ZHANG Xue-ting,TANG Yong,LIU Jing-biao,HUANG Kong-yao . Design of AMR electronic compass [J]. Journal of Tropical Oceanography, 2009, 28(4): 49-53. |

|

||